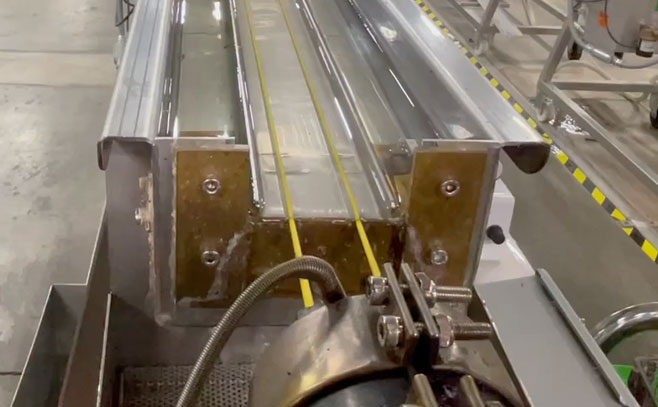

Mitsubishi Chemical’s Performance Polymers 3D Printing Division specializes in research & development, compounding, extrusion, customized packaging and rewinding for FDM/FFF/FGF materials with several production facilities around the world.

We can provide solutions for the biggest issues facing large scale 3D-printing such as melt flow, bed adhesion, warpage/shrinkage, rigidity/flexibility, layer adhesion, and much more.

We utilize our extensive material science knowledge and expertise in additive manufacturing to provide the growing Fused Granular Fabrication (FGF) market with a full range of material solutions to bring this segment towards a new stage of growth. We provide added value to our customers by combining collaboration, design, material modification, and printing expertise to optimize solutions for each project.

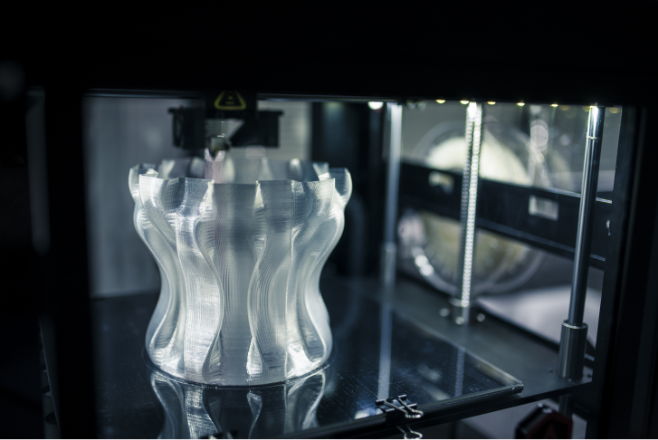

Diakon™ polymers from MCC are known for their easy processability, excellent optical clarity, high light transmission, toughness and high scratch and impact resistance. We have now taken this well-known material and developed 3Diakon™—a transparent 3D printable polymethyl methacrylate (PMMA) filament. 3Diakon™ has excellent weathering and UV stability combined with excellent impact performance and stiffness.

Mitsubishi Chemical’s DURABIO™ HI 3D filament for FFF/FDM printing is a bio-based material that is a truly durable engineering plastic that is made from isosorbide (derived from sorbitol), a widely available feedstock. In addition to being environmentally friendly, DURABIO™ material also combines the advantageous properties of Polycarbonate (PC) and those of the Polymethyl methacrylate (PMMA), creating an innovative renewable material with extraordinary properties.

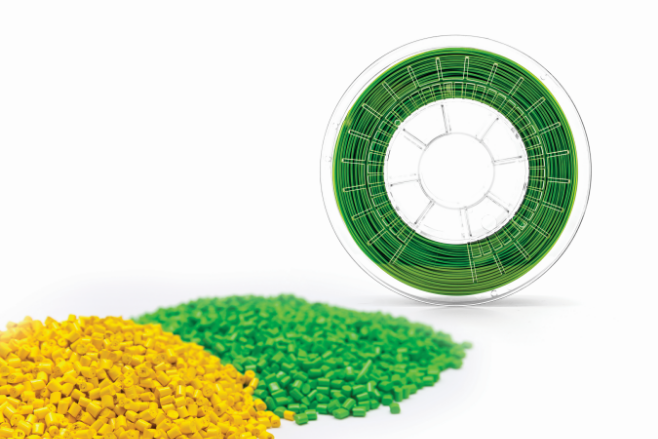

Derived from renewable material and known for superior ambient compostability, BioPBS™ is an excellent solution for developing environmentally friendly products. BioPBS™ (partially bio-based polybutylene succinate) is revolutionary in its two-fold bio properties.