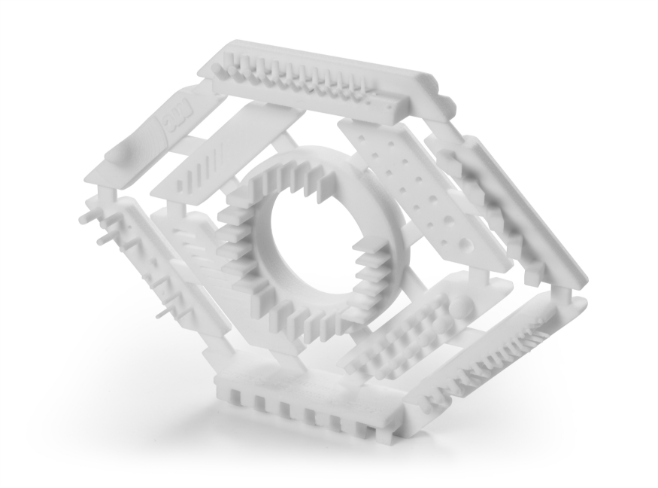

Mitsubishi Chemical partnered with AM Polymer, to co-develop Rolaserit™ SLS powder bed fusion PBT powder to optimize energy input for rapid prototyping. The enhanced polymer design provides lower moisture absorption, high-strength and high heat resistance characteristics, as well as the ability to create lightweight components.

The manufacturing, from co-polymerization to compounding technology, enable recycling of unused powder for utilization in subsequent prints. Rolaserit™ delivers enhanced features and unlocks premium benefits from the first prototype through serial high-volume production.

Download the Technical Data Sheet

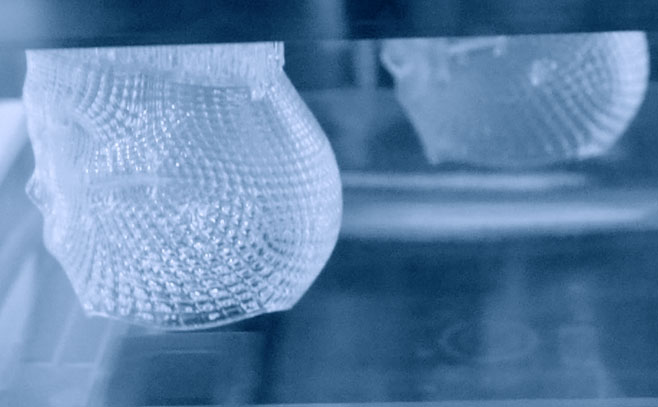

DIABEAM is a specialized SLA/DLP resin for vat polymerization. DIABEAM is unlike any other resin on the market, with specific properties offering an excellent balance between heat deflection temperature (HDT) and impact strength (Izod). The UV resin can solidify under a 365 nm light source while providing high scratch resistance with low odor and skin irritation. Excellent solution for 3D printing automobile interior trim parts.