Manufacturers across the globe face the same challenge—the high cost and long lead times for tooling is killing good products before they are even launched. Additive manufacturing has become a go-to for rapid prototyping for many projects, but the Z-direction strength and material selection have been limiting factors in some industries.

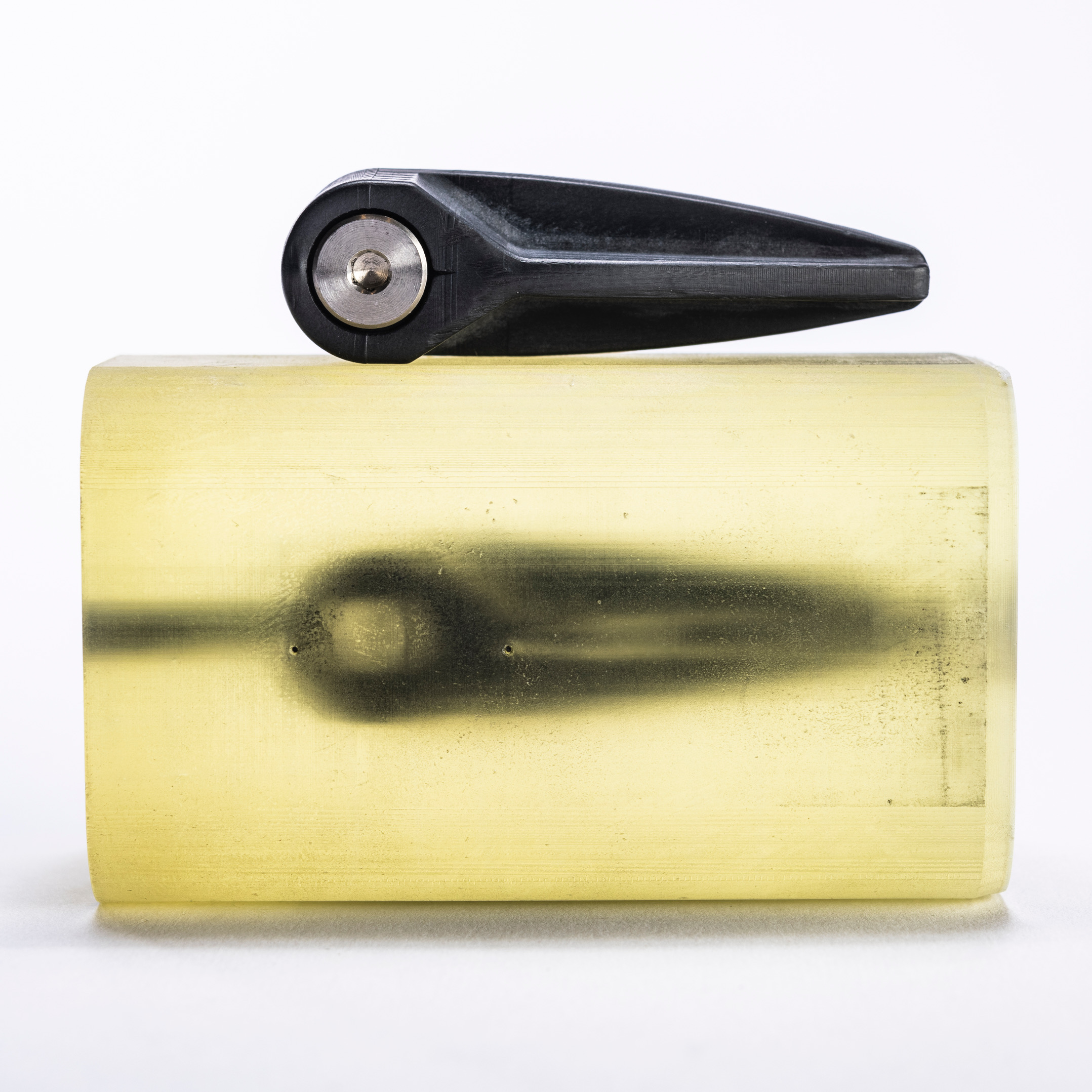

AddiFab’s proprietary Freeform Injection Molding (FIM) process solves those problems. FIM is a hybrid additive manufacturing solution that blends the best of additive manufacturing and injection molding technologies, resulting in isotropic parts from real injection molds in days instead of months.

The SPRINT Process opens new possibilities for design engineers for total life-cycle management by integrating new components into industrial applications, seamless integration across rapid prototyping, mass customization, volume production and after-market parts.

Material Development – Tailored materials for 3DP applications – large format and small format

Sustainability – Driving development of 3DP materials utilizing recycled materials

Prototyping Capabilities – A variety of prototyping methods to fit all applications

Scalability – Ability to use KyronMax materials for 3DP prototyping and the transition into same material for larger scale production

Metal-to-plastic converstions, without the cost and lead time of traditional metal tooling or the penalties for multiple design changes

Prototype parts using the same resins as production injection molded parts

Puts functional parts with isotropic properties into customer’s hands quickly to accelerate the design cycle and lock in material specifications

Surface finishes and features that cannot be replicated by machinging or 3D printing