Lucite International – It’s no surprise that acrylic is all around us; we come across it being used in and around towns and cities, art and architecture, in our homes and vehicles, even at sea. What may come as a surprise, however, is that acrylic is often used within the health and medical sector, helping to improve our lives in multiple ways.

Since 1945, our Colacryl® branded range of acrylic polymers has been under continuous development with the world’s largest dental manufacturers. These unique products allow dentists to create super-strong prosthetic teeth with both superior fit and outstanding aesthetics. From heat cure denture polymers, repairs and relines to orthodontic polymers characterised by close control of particle size, free flow and rapid absorption of dental liquid, our products come with the very best range of performance qualities.

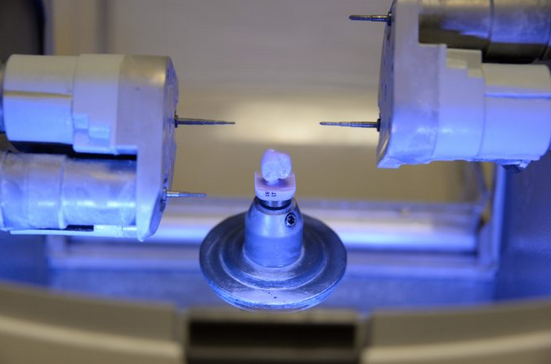

Over the past decade, computer-aided dentistry has become increasingly valuable in reducing waiting times and improving patient care. Unlike traditional temporary dental crowns, CAD/CAM dental implants can be created using acrylic polymers in a matter of hours, saving time for dentists, and discomfort for patients!

Lucite International’s Colacryl® acrylic resins are also used by global leaders in the field of bone cement where consistent, long-term high performance is paramount. Using our long heritage of development and manufacturing knowledge and experience, we continue to work with researchers, manufacturers and surgeons to continuously improve our bespoke formulations to ensure we stay at the leading edge of this important sector.

New-born babies require the best possible care and protection. With hygiene being a critical factor for keeping them safe in hospitals, bassinettes made from acrylic are a perfect choice; their ultra-smooth surfaces are easy to clean and stay cleaner for longer. Acrylic’s excellent optical clarity also allows for easy monitoring while offering maximum protection for the new-born.

Excellent transparency and optical clarity, UV resistance and surface hardness coupled with good chemical resistance make Diakon® acrylic polymers ideally suited for the manufacture of disposable medical diagnostics. Blood cuvette-, drug testing device-, and laboratory equipment manufacturers benefit from easy processing, purity of material, good dimensional stability and excellent bonding capability with itself and other polymers.

Acrylic resin can also be used in the medical industry as a coating for flooring. In areas of high traffic, where high durability and hygiene are of significant importance, acrylic coatings can be easily cleaned and maintained.