Mitsubishi Chemical Corporation (MCC; Head office: Chiyoda-ku, Tokyo; President: Masayuki Waga) has decided to establish a new pilot facility for carbon fiber reinforced thermoplastic (CFRTP). The facility will be located in Fukui Prefecture and is scheduled to start operation by the end of 2021.

MCC has an extensive track record of successfully using CFRP in applications such as automobiles, and the company has a wealth of technologies relating to carbon fiber and plastic modification. With support from the Industrial Technology Center of Fukui Prefecture and leveraging technological synergy within the MCC Group, MCC has recently established technology enabling highly efficient manufacturing of extremely high-quality CFRTP with low void content. In the future, MCC will market the product as a new series in its KyronTM thermoplastic composite brand and roll it out to the Japanese CFRTP market, which until now has relied chiefly on imported products.

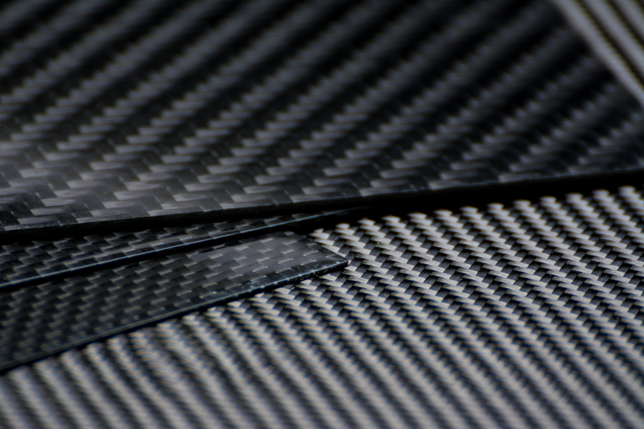

Against a backdrop of tighter environmental regulations, needs for lighter aircraft and automobile bodies are growing in the mobility sector, and use of CFRP is predicted to increase, since it is both light and strong. Until now, CFRP using thermosetting resin has been the main product in this segment, but to promote CFRP utilization, more widespread use needs to be made of CFRTP, which enables shorter component production times and is easy to recycle.

MCC has world-class technology relating to PAN-based and pitch-based carbon fibers as well as thermoplastics ranging from general-use grades to highly heat-resistant products. The company will proactively expand its CFRP business by harnessing the power of the entire MCC Group to develop new products capable of fulfilling increasingly diverse and sophisticated customer needs and providing optimal and timely solutions to the mobility sector, where remarkable technological innovation is taking place.